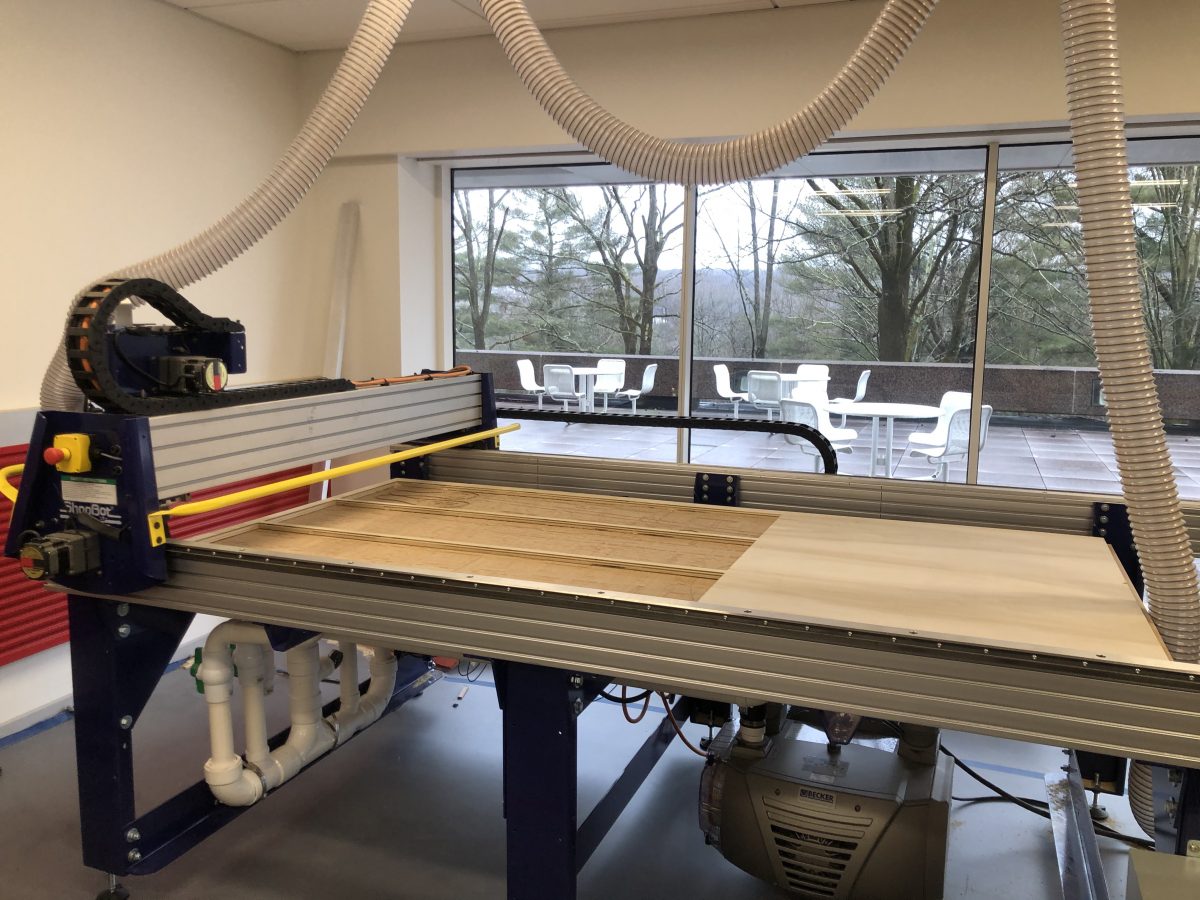

In this training, you will learn the basics of the ShopBot and how to operate the machine safely.

To be allowed to use the ShopBot, you must watch all training videos, 100% the required quiz, and perform a test print to show that you are able to use the machines safely.

Training Videos

Introduction Video

In This Video, You Will Learn:

- Basics

SHU Specific Rules & Procedures Video

Intro

- Hello i’m Graham the shop facilitator.

- To complete this training and get the shopbot badge which will give you permission to use the shopbot with a facilitator in the shop, you have to watch this video and all other attached videos, take the online quiz and then attend the in person training.

- Requirement for this badge: Basic shop safety

Safety

- When operating the Shopbot you must wear:

- Safety glasses

- Ear protection

- Closed toe shoes

- Tidy up anything “loose” such as necklaces

- No jewelry on your hand.

- A facilitator MUST be present at all times.

- While in operations, you must stand behind the safety line (red tape on the floor).

- Jobs must be validated by a facilitator BEFORE start.

Supplies (aka getting wood and getting rid of it)

- You can bring and use any of the materials listed on the machine page HERE.

- If you need to store any materials for more than a day, please contact a facilitator. By default, any materials found in the lab is considered “free use”.

- Free scraps are available, please ask the facilitator.

Loading

- For large pieces, 2 people are required. A facilitator can help you!

- Make sure the material is flat and cornered on 0/0

- Clamping technique / vacuum holding

Powering the Shopbot

- Gantry / bed / spindle / buttons / tools / vaccum

- direction / where is the 0/0 located

- how to turn everything on

Changing bit

- Checking current bit size

- Changing bit/collet

- Secure new bit

VCarve

- Importing your design (+accepted formats)

- Creating Toolpaths

- Path tool

- Pocket tool

- Vcarve tool

- Dog Bones / T Bones

-Defining the job - Choosing the right bit

- Feeds and speeds

- Troubleshooting

- Scale/dimensions

- Closing path

- Cutting extra paths

- Checking directions

- Toolpath order

-Exporting from VCarve to the Shopbot

Shopbot control

- Zeroing the machine

- Loading .SBP file

- Facilitator validation!!!!

- Dust collection on

- Vaccum on

- Starting the job / checks while operating

- Troubleshoot (depth, size, direction, etc….)

Cleanup

- Vaccum

- Unusable scrap

- Reusable scrap

Wrap up

- Thanks

- Take quizz next + in person training to validate your badge

- Hours of operation (When can they use it)

Take the Quiz!

Test files

Cheat Sheet:

- You need a facilitator in the room and before you run a job have a fascinator check the job out.

- Make sure to calibrate all your axis’s

- Make sure your cuts are on the right side of the part i.e. inside and outside

- Make sure to have vacuum on when leveling bed.

- Make sure to turn on vacuum and dust collect when running job.

Facilitator

Bryan Bushey

Monday: 12:45 pm – 2:30pm

Tuesday: 1:30 pm – 2:30 pm

Wednesday: 5:30 pm – 8:00 pm

Thursday: 12:45 pm – 2:30pm | 6:00 pm – 10:00 pm

Friday: 12:00 pm – 2:30pm | 5:00 pm – 6:30 pm