by Bryan Bushey and Trevor Neal

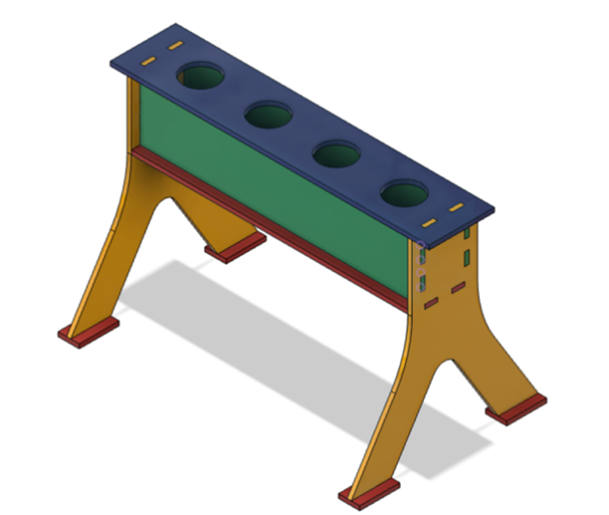

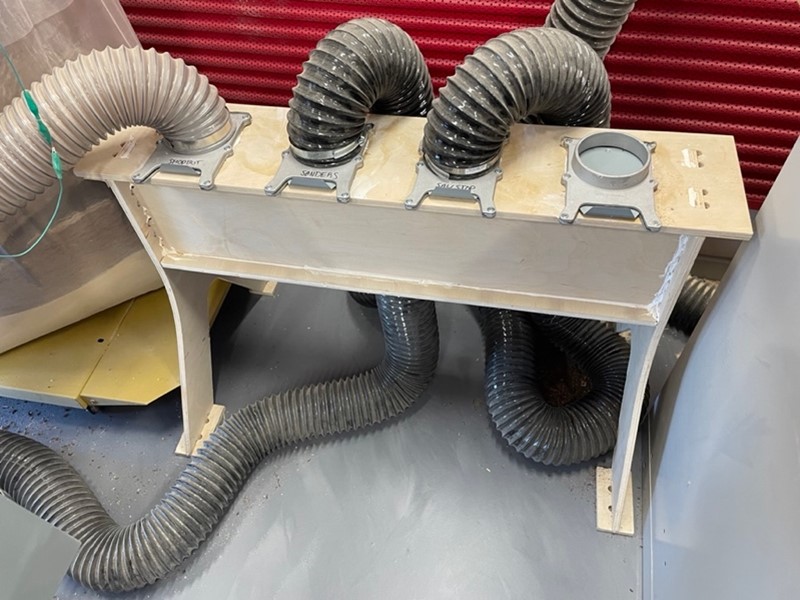

Within the machine shop we have many wood working machines that need vacuuming to keep the air clean and breathable. The vacuum in the shop is a PowerMatic with dual filters and bags. With the loss of suction by hooking up the three other machines to the vacuum created a loss of suction to the ShopBot. This was causing a lack of a safe operation. A challenge with the ShopBot is making sure there is no build-up of sawdust around the drill bit. When there is flammable sawdust near a drill bit, it creates a massive amount of friction that can only lead to one problem. To solve this, I designed and built a four-way switch. The gates on every outlet. This allows me to turn off the vacuum to certain machines and give power to the one in use. The previous method for this was physically removing and replacing the 4-inch pipe.

One issue for designing was keeping an air-tight seal. By using finger joints, this opened holes in the final product for the CNC paths of the production. With the help of Trevor Neal, he created 3D printed plugs to fill the holes along with a silicon caulk gun to fill the seams between planes.